|

Gainesville FL (SPX) Jul 22, 2010 Surface tension isn't a very powerful force, but it matters for small things - water bugs, paint, and, it turns out, nanowires. Nanowires are so tiny that a human hair would dwarf them - some have diameters 150 billionths of a meter. Because of their small size, surface tension that occurs during the manufacturing process pulls them together, limiting their usefulness. This is a problem because the wires are seen as a potential core element of new and more powerful microelectronics, solar cells, batteries and medical tools. But in a paper in the journal ACS Applied Materials and Interfaces now online, a University of Florida engineering researcher says he has found an inexpensive solution. Kirk Ziegler, an assistant professor of chemical engineering, said nanowires are most often made today with a process that involves the immersion of the wires. When complete, each wire is supposed to poke up right next to the other from a flat surface, like bristles on a Lilliputian toothbrush. But Ziegler said the wires are so tiny and so flexible that surface tension clumps them up when dried. Manufacturers use extremely high pressure to reduce the surface tension, but Ziegler said that process is difficult, expensive and not conducive to large-scale production. Ziegler and Justin Hill, who will graduate from UF with a doctorate in chemical engineering this summer, realized that they needed to introduce a force that counteracted that of the surface tension. They came up with a process simple enough to be achievable with a nine-volt battery. The researchers apply an electrical charge to the nanostructures during the manufacturing process, charging each tiny wire and making it repel its neighbor. "As the two nanowires pull toward each other because of the surface tension, the like charges at the tips act to push them apart," Ziegler said. "The aim is to get a net zero force on the structure, so the nanowires stand straight." Tests of microscope-slide-sized surfaces, each containing trillions of nanowires, showed that the procedure effectively prevents clumping, Ziegler said. Nanowires have not found wide commercial applications to date, but Ziegler said that as engineers learn how to make and manipulate them, they could underpin far more efficient solar cells and batteries because they provide more surface area and better electrical properties. "Being able to pack in a higher density of nanowires gives you a much higher surface area, so you start to generate higher energy density," he said. Ziegler said that biomedical engineers are also interested in using the wires to help deliver drugs to individual cells, or to hinder or encourage individual cell growth. The University of Florida has applied for a patent on the process, he added.

Share This Article With Planet Earth

Related Links University of Florida Powering The World in the 21st Century at Energy-Daily.com

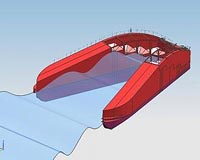

Ocean energy industry wants support

Ocean energy industry wants supportBrussels (UPI) Jul 20, 2010 Ocean energy could provide 15 percent of Europe's energy needs by 2050, the industry says, adding that this target is only realistic if politicians increase support for the new technologies. "Europe has the oldest maritime industry, vast ocean energy resources and it is a pioneer in ocean energy technologies. It is well-positioned to lead the world in harvesting ocean energy," the Europ ... read more |

|

| The content herein, unless otherwise known to be public domain, are Copyright 1995-2010 - SpaceDaily. AFP and UPI Wire Stories are copyright Agence France-Presse and United Press International. ESA Portal Reports are copyright European Space Agency. All NASA sourced material is public domain. Additional copyrights may apply in whole or part to other bona fide parties. Advertising does not imply endorsement,agreement or approval of any opinions, statements or information provided by SpaceDaily on any Web page published or hosted by SpaceDaily. Privacy Statement |