|

Bonn, Germany (SPX) Jul 16, 2009 Photovoltaic and wind energy plants, hydroelectric power stations and biogas plants supply energy without polluting the environment. However, they are complex to design and maintain. Virtual reality (VR) makes planning and operation easier. The design engineer's head is spinning. He has been analyzing data on his computer for hours, with no end in sight. Designing a hydroelectric power station, he would like to know what the pressures, temperatures and fluid flows will be in the facility. He may simulate them with simulation software. However, this only delivers vast columns of numbers or a one-dimensional representation which he will have to analyze bit by bit - a laborious task. This will get easier in the future. Researchers from the Fraunhofer Institute for Factory Operation and Automation IFF in Magdeburg have developed a method that visualizes the processes inside energy conversion plants, e.g. such as photovoltaic, wind, biogas and hydroelectric power stations. To do so, they have coupled 3-D plant engineering and simulation results with a virtual reality (VR) program developed at the IFF. "A special software tool has enabled us to visualize all the motion sequences for the first time ever - at just the push of a button," explains Dr. Matthias Gohla, Manager of the Process and Plant Engineering Business Unit. Arrows that move through the VR model show engineers the direction in which and speed at which fluids and gases flow through a plant. Colored markings indicate potential weak points such as areas where critical temperatures, deposits or erosions could occur. Is there a potential for collisions when the plant components are moving? The virtual insights facilitate engineering and should therefore ensure that plants become more efficient and have lower emissions. "Our VR model also helps plant operators in day-to-day operation," says project manager Dr. Martin Endig. For instance, extensive documentation may be implemented in the system. Instead of hunting through thick instruction manuals for desired information, a technician merely needs to click on the appropriate representation to obtain data on a certain plant component. Moreover, personnel can be trained to handle a plant before it is operational. Even critical situations can be simulated without endangering employees. Currently, the developers are working on another tool that notifies operators when a component is due for maintenance. Share This Article With Planet Earth

Related Links Fraunhofer-Gesellschaft Powering The World in the 21st Century at Energy-Daily.com

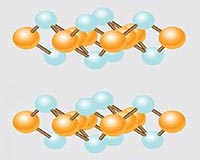

Superconductivity: Which One Of These Is Not Like The Other

Superconductivity: Which One Of These Is Not Like The OtherWashington DC (SPX) Jul 16, 2009 Superconductivity appears to rely on very different mechanisms in two varieties of iron-based superconductors. The insight comes from research groups that are making bold statements about the correct description of superconductivity in iron-based compounds in two papers about to be published in journals of the American Physical Society. The 2008 discovery of high-temperature superconductiv ... read more |

|

| The content herein, unless otherwise known to be public domain, are Copyright 1995-2009 - SpaceDaily. AFP and UPI Wire Stories are copyright Agence France-Presse and United Press International. ESA Portal Reports are copyright European Space Agency. All NASA sourced material is public domain. Additional copyrights may apply in whole or part to other bona fide parties. Advertising does not imply endorsement,agreement or approval of any opinions, statements or information provided by SpaceDaily on any Web page published or hosted by SpaceDaily. Privacy Statement |